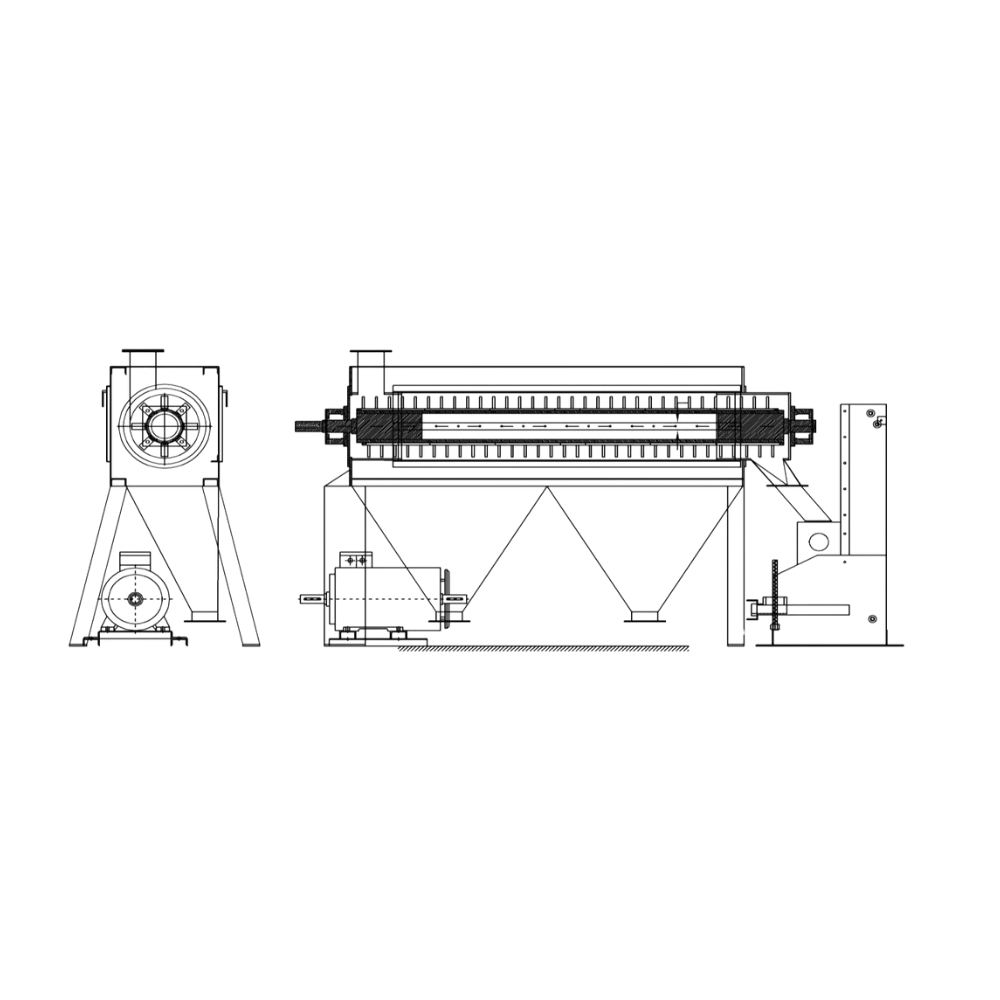

A horizontal scourer works by tumbling grain against a high-speed rotor and a perforated screen to physically abrade and remove surface impurities like dust, dirt, and loose husk. The grain is fed tangentially into the cylinder, where it is repeatedly struck by the rotor blades and rubbed against the screen, a process that also involves friction between grain particles. The separated impurities pass through the screen holes, are collected, and are removed, often with the help of an integrated aspirator.