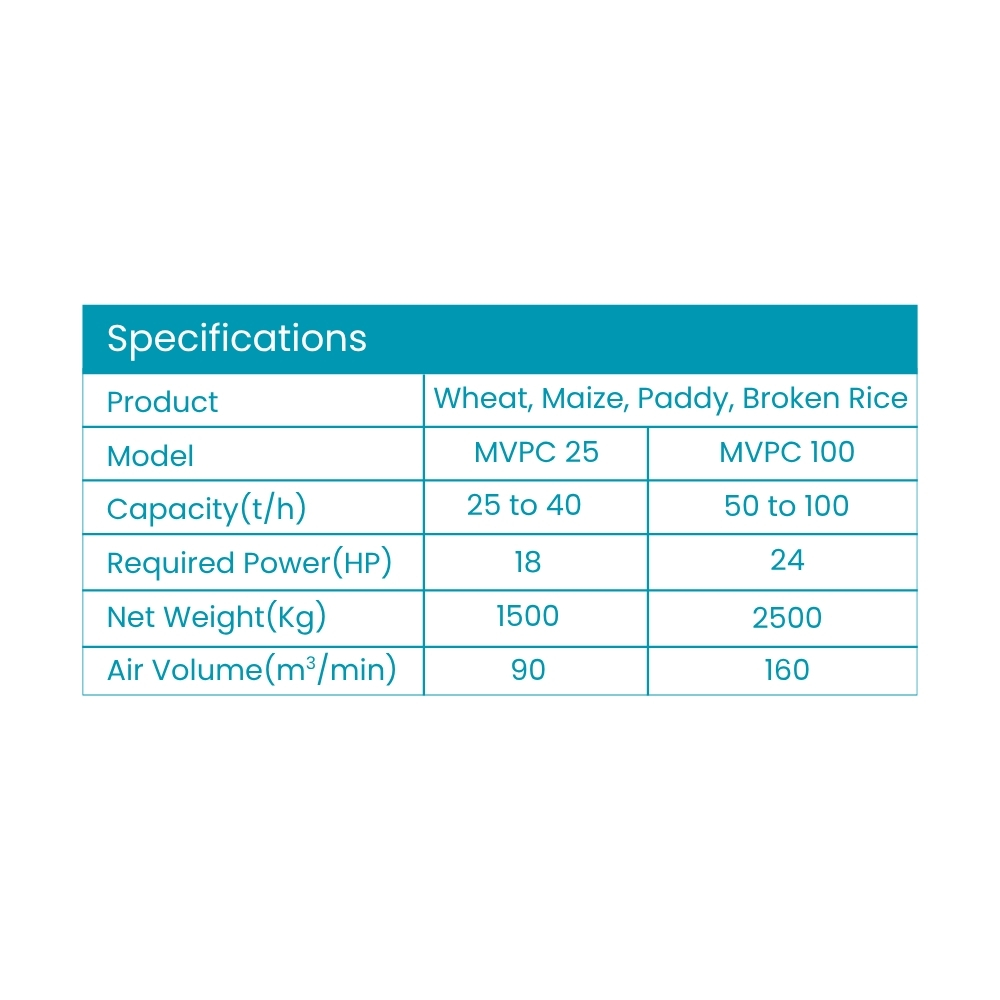

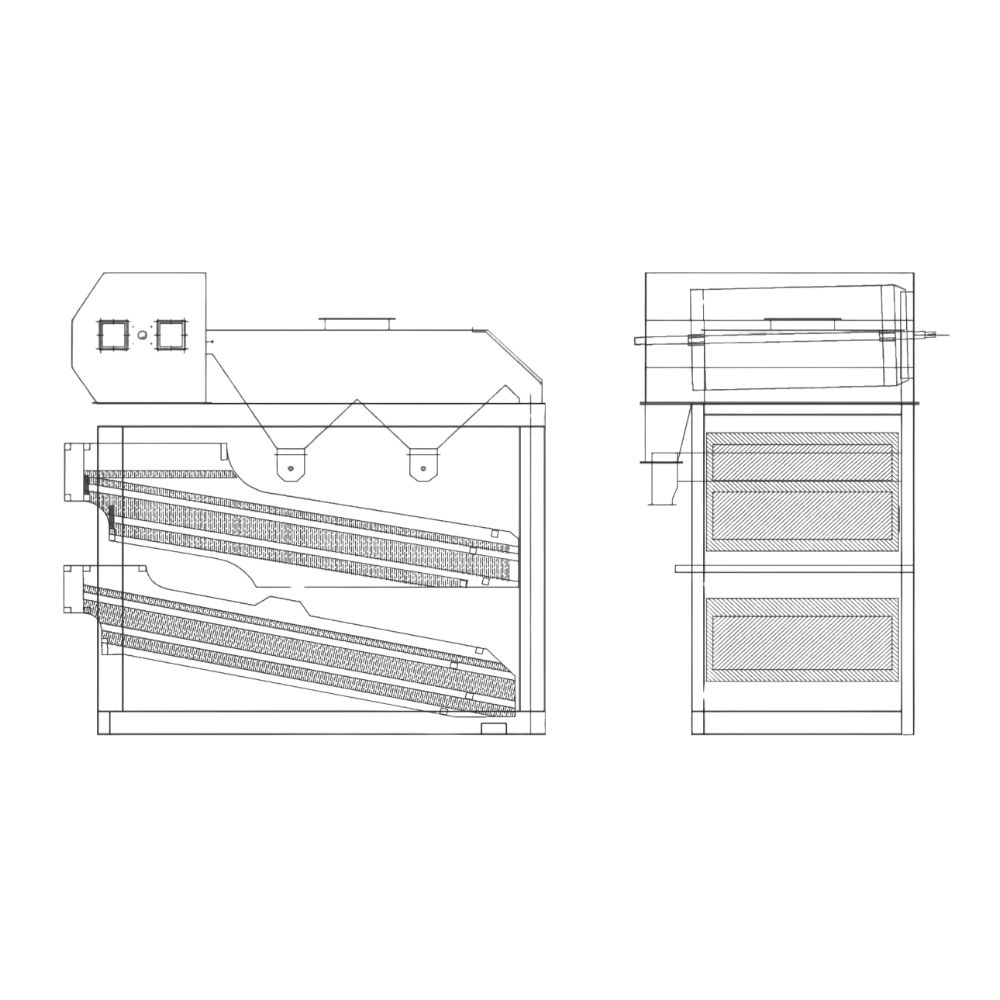

Grain Pre-Cleaner is used for pre-cleaning operations having capacity up to 100tph on wheat, maize and 65tph on broken rice. A pre-cleaner machine works by using a combination of sieving and aspiration to separate unwanted materials from harvested grains and other raw products. The raw product is fed onto a series of vibrating screens (sieves) that separate particles by size. Simultaneously, an aspiration system with a built-in blower removes lighter impurities like dust, small stones, and other debris by suction, often directing them to a separate collection point.