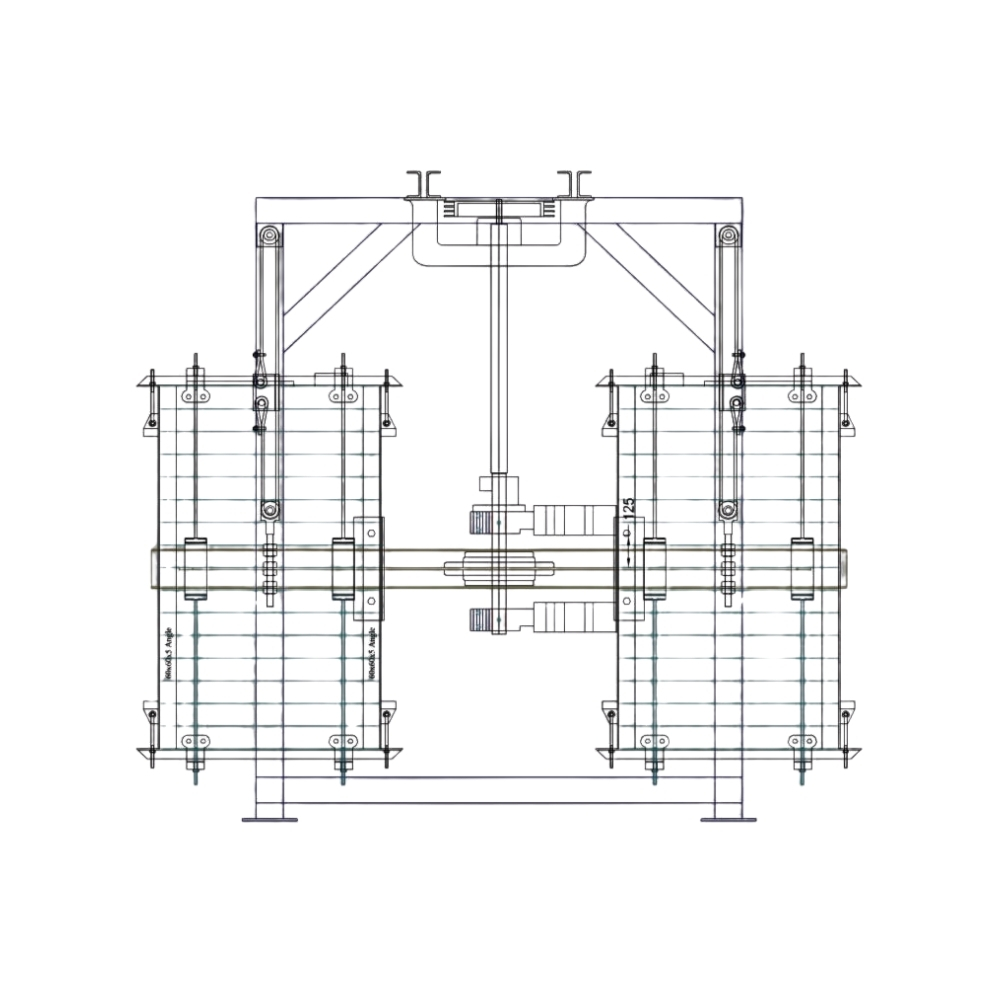

A plansifter classifies materials by size using a series of stacked, square sieves that are set in motion by an eccentric weight or a motor. The sifting motion, a combination of shaking and rotation, causes the material to flow across the screens, allowing smaller particles to pass through while larger particles remain on top. The material is fed in at the top and the separated product is discharged at the bottom, with multiple outlets to collect different grades or sizes of material.